How are cosmetic glass bottles made?

May 30, 2024

The most basic process for making cosmetic packaging is glass packaging manufacturing. The raw materials for making glass are generally quartz sand, sodium carbonate, and limestone. Mix these raw materials in a certain proportion, melt them in a high-temperature furnace, and then use a fiberglass machine to adsorb the melted glass onto the fibers. After rapid cooling, form glass tubes or discs.

1. Forming

The glass tubes are cut, heated, and blown into different shapes of glass bottles, such as circular, square, trapezoidal, etc.

2. Cutting

Cut the glass tube or disc into the desired length and use a cutting tool for cutting.

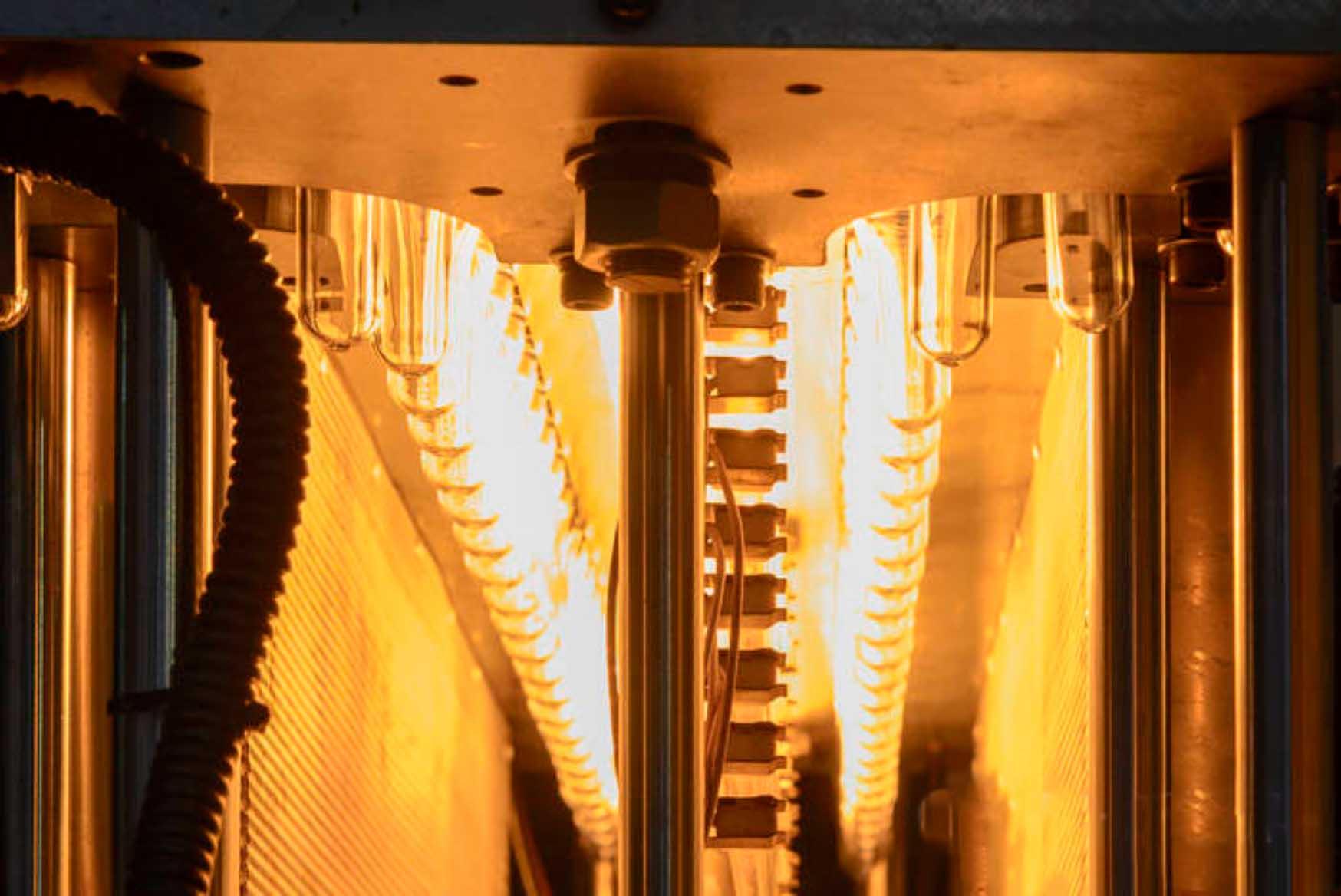

3. Heating

Put the cut glass tube or disc into a special heating furnace and heat it to a certain temperature to soften the glass. This can make the bottle easier to shape during blowing, while also reducing the probability of producing bubbles and burning points.

4. Blow molding

After heating, a certain amount of gas is blown into the interior of a glass tube or disc through a glass blowing tube, causing it to expand into the shape of the bottle body. When blowing, different shapes of glass bottles require different blowing tools. Then use a machine to modify the shape of the bottle to increase its aesthetics.

Network Supported

Network Supported