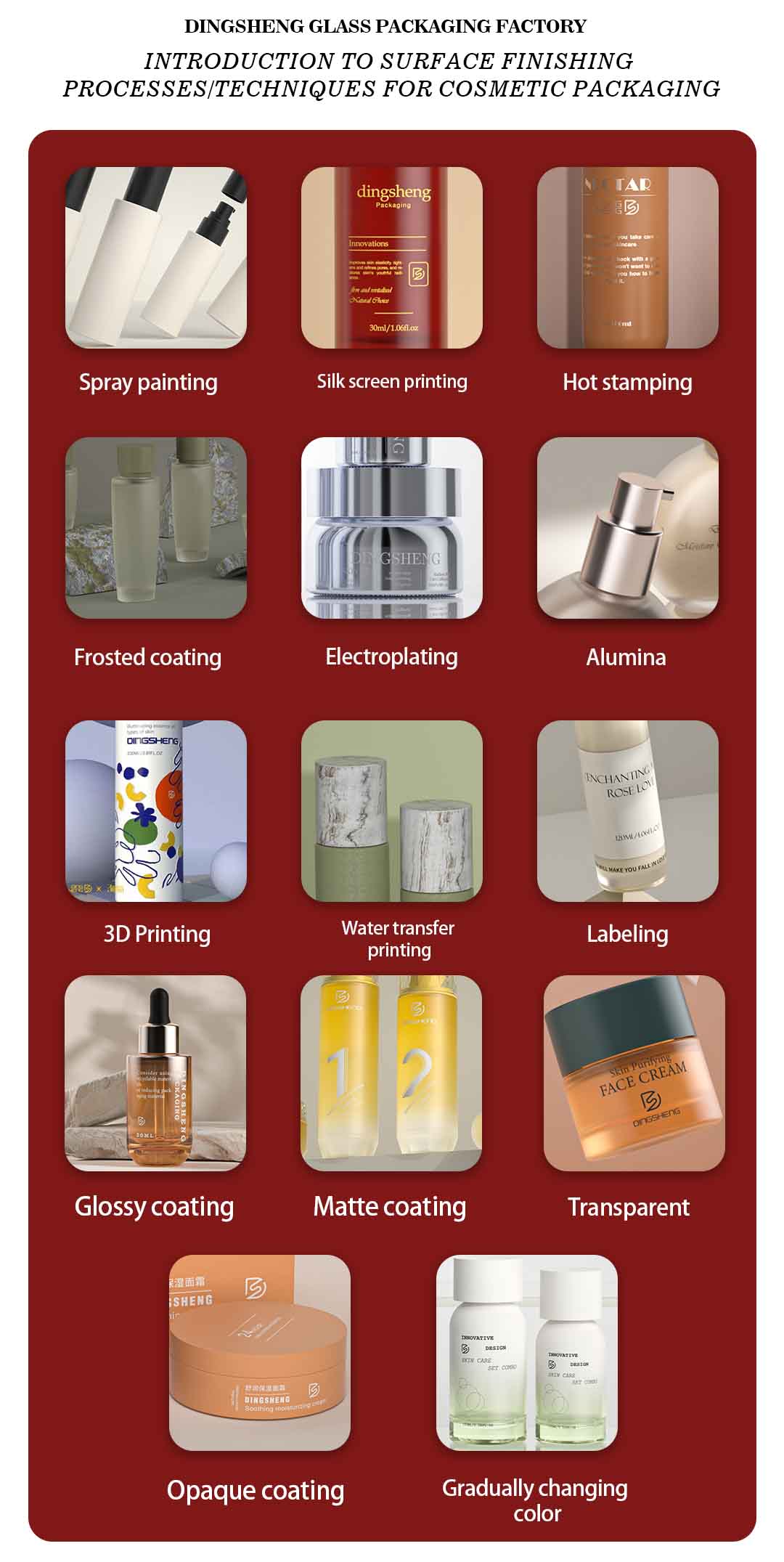

Spray painting: The process of uniformly spraying water-based paint onto the surface of a cosmetic glass bottle

using a spray gun. In addition to color, there are usually differences such as translucent, solid, glossy, matte,

gradient, and the addition of pearl powder.

Silk screen printing: Printing is carried out using the basic principle that the graphic and textual parts of the

screen printing plate can pass through ink, while the non graphic and textual parts cannot pass through ink

through the mesh holes. Print text, capacity, brand name, product introduction, etc. on glass bottles.

Hot stamping: By heating, gold or silver aluminum foil is attached to the surface of the packaging, giving it a

textured and strong metallic feel. Create a luxurious feel for the product.

Frosting: Chemical materials such as sandblasting solution (powder) are soaked, sprayed, etc. to attach the

material to the surface of a glass bottle, forming a frosted effect on the surface through chemical means.

Electroplating: Using chemical reactions in an electrolytic cell to form a uniform and dense metal coating

on the surface of a glass bottle. After electroplating, the surface of the glass bottle will present a metallic

luster and texture, making the bottle look high-end and exquisite.

Aluminum oxide pump: Made of metal material, select suitable aluminum oxide raw materials and appropriate

additives to mix evenly, and press them into shape through a mold with external pressure. Aluminum oxide

pump head has strong wear resistance, good corrosion resistance, and high temperature stability.

3D printing: It is mainly a technology that uses digital model files as a basis to construct objects through layer

by layer printing. 3D printed text or printing has a textured texture.

Water transfer printing: It is an irregular printing technology that is placed in water, with rich layers of printed

patterns, bright colors, and endless variations.

Labeling: refers to the process of attaching labels or identification materials to containers. Low cost and good

environmental performance.

Bright surface: The surface of the glass bottle is coated with glossy oil, and the packaging material looks very

shiny.

Matte surface: The surface of the skincare glass bottle is coated with matte oil to create a matte effect.

Semi-transparent: The cosmetic packaging material has a transparent feel.

Opaque color: The packaging material has no transparency.

Gradient color: The surface of a glass bottle is sprayed with different colors and gradually transitions naturally,

forming a smooth change in color.

Sitemap Blog Xml Privacy Policy

Copyright @2024 Dingsheng (Guangdong) Glass Technology Co.Ltd. All Rights Reserved.  Network Supported

Network Supported